In industrial settings, choosing between a soft starter and a variable frequency drive (VFD) can be pivotal in optimising motor performance, efficiency and cost-effectiveness. Both technologies serve the purpose of controlling motors, but their application, benefits and limitations vary significantly.

Ali Khalil, Development Sales Manager for high voltage solutions at industrial equipment manufacturer WEG, explains that deciding when to use a soft starter instead of a VFD involves assessing four key factors: speed control, price, size and energy efficiency.

While variable frequency drives (VFDs) are versatile and suitable for almost all applications, soft starters are more specific in their use cases. This doesn’t mean that VFDs are easier to specify, install and commission – it simply means they apply to a wider variety of scenarios. Let’s explore when you should choose a soft starter over a VFD.

When smooth starts are enough

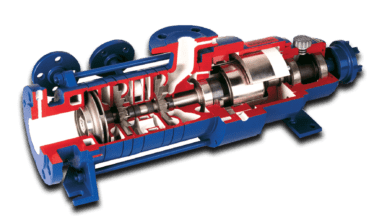

The primary distinction between a soft starter and a VFD is how they control speed. A soft starter gradually ramps up the voltage to allow the motor to start smoothly, minimising torque and mechanical stress during the startup phase. However, once the motor reaches full speed, a soft starter cannot provide any additional speed control. This makes soft starters ideal for applications in conveyors, pumps and fans, where motors only need to operate at full speed and the primary concern is reducing inrush current and mechanical stress during startup.

Therefore, a VFD is the clear choice when an application requires consistent speed adjustments and torque control throughout the motor’s operation. However, a soft starter is a more efficient option for applications that do not need speed control beyond startup.

Weighing the cost of simplicity versus advanced control

Cost is another critical factor when deciding between a soft starter and a VFD. Soft starters are generally more affordable due to their simpler design and functionality. A soft starter uses silicon-controlled rectifiers (SCRs) to connect the AC input line to the motor. In contrast, VFDs incorporate more complex components, including a diode front end, DC bus and insulated-gate bipolar transistors (IGBTs), which increase costs.

This additional complexity makes VFDs more expensive, often two to three times the price of a soft starter, especially for larger horsepower applications. However, the higher initial cost of a VFD can sometimes be justified by its potential to deliver long-term energy savings, particularly in applications where motors frequently run at partial loads or variable speeds.

Maximising space with compact solutions

The next consideration should be size. Soft starters also offer substantial savings in physical size and volume compared to VFDs. The additional components in a VFD and its cooling system cost more and take up more space. The volume savings with a soft starter depend on the power rating. In industries where space is limited, such as shipyards or small manufacturing facilities, the smaller footprint of a soft starter can be a crucial advantage. The reduced size and complexity also mean that soft starters are easier and quicker to install, further reducing operational costs.

Instant efficiency gains or long-term savings with speed control

Finally, energy efficiency should be considered. Soft starters can achieve up to 99.5 to 99.9% efficiency. After the starting process, a soft starter with an integrated bypass activates an internal contactor, allowing current to flow through it efficiently. In contrast, VFDs are around 95% efficient because active components like IGBTs are always on during start, run and stop phases, leading to lower efficiency. However, VFDs offer more opportunities for energy savings by controlling both voltage and frequency.

When operating at full speed and properly loaded, soft starters are more efficient than VFDs. Once up to speed and bypassed, the motor current flows across the bypass contactor in a soft starter, with no active solid-state components generating heat. Conversely, a VFD remains hotter due to its active components constantly managing voltage and frequency.

Properly selected soft starters can yield significant cost, size and energy savings over VFDs. The latter can be two to seven times more expensive and two to eight times larger than soft starters, but application characteristics are critical when choosing between the two options.

Both can start a motor with reduced voltage and current, but the unique aspects of your application will determine the best choice, allowing you to right-size either a soft starter or a drive. Regardless of the motor control method you choose, consider additional factors such as installation, commissioning and the need for extra filters or circuit protection when specifying a soft starter or a VFD.

Visit WEG’s website to learn more about the company’s range of soft starters and VFDs.