Open up predictive maintenance with a reliability partner

Akshat Sharma, Global Monitoring & Controls Manager at ITT, looks at the benefits of taking a predictive approach to plant maintenance with condition monitoring, and explains how working with a reliability partner can overcome some of the barriers to its adoption.

We live in a world full of machines. From cell phones and cars to the pumps we manufacture and the industrial plants where they operate, we’re living in an age of technology never seen before.

Unfortunately, we also live in an age where machine unpredictability is a constant challenge. And while installing updates on our cell phones or getting routine maintenance on our cars is part of life, machine downtime in an industrial facility leads to lost time, money, and resources. Fortunately, the same advancements in technology that have brought about these new machines have also revolutionised how we monitor and maintain equipment.

Reactive vs Preventative vs Predictive

The challenge many facility managers face is that most of their maintenance falls into one of two buckets: reactive or preventative.

Reactive maintenance is simply corrective actions that happen after a breakdown. Extending the car analogy above, this would be taking your car to the shop after you get a flat tire. In other words, you have a problem, so you get it fixed. That’s great if you’re near a tyre shop, but if you’re out on the road, you’re looking at significant costs and lost time, in addition to a potentially dangerous situation.

It’s also easy to see how this applies to the industrial world. If a machine breaks, the repair process can be tedious, often needing a multistep diagnostic process since machine issues aren’t as easy to diagnose as a flat tyre. And if you don’t have the right technology or service in place, it could drain resources by requiring multiple different employees to collect and analyse data before determining a solution. And every minute the machine is down, that could be hundreds or thousands of dollars in lost revenue.

To avoid these critical issues, many facility managers turn to preventative maintenance plans instead. Once again, using the car analogy, this would be the equivalent of rotating your tires every three to six months and checking the tire pressure routinely when you stop to fill up your tank. This is certainly better than simply relying on reactive maintenance, but once again, you’re incurring costs to take the car (or machine in industrial settings) out of commission to check for problems that may or may not exist. And there’s still no guarantee that a problem won’t arise between these check-in points and cause a significant headache.

Therefore, what we’ve seen in recent years is the advancement in technology that leads us to the future of maintenance, which is called predictive maintenance. In the car example, this would be the dashboard function that constantly measures your tire pressure, alerting you as it starts to drop and letting you know which tire may have a small leak.

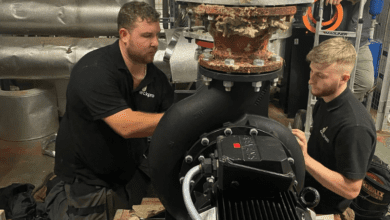

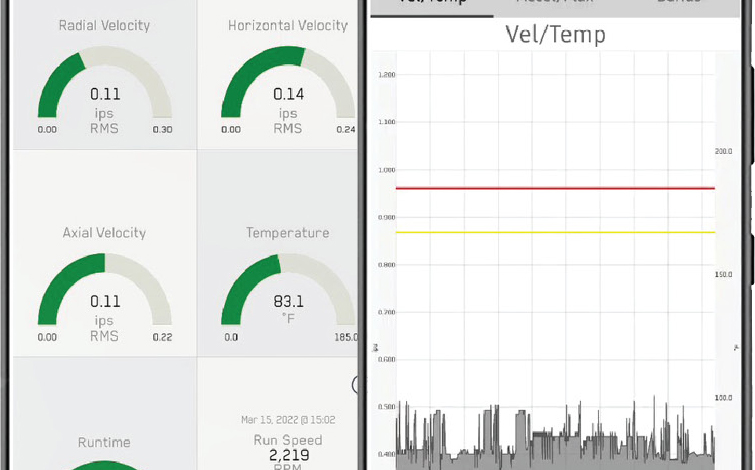

In the industrial world, it’s the use of smart sensors that work by monitoring and logging different parameters such as vibration, speed, pressure and temperature, thereby capturing transient events and malfunctions in real time. This data can be quickly processed to identify developing issues and establish potential solutions. However, this takes knowledge and experience that industrial businesses don’t necessarily have in house.

But this doesn’t have to create a barrier. By working with a reliability partner with knowledge and experience, predictive maintenance, enabled by real-time condition monitoring, can offer substantial benefits.

Flexibility of services

Companies can choose to be hands on with their analysis of this data or work with a monitoring partner who will ensure that problems with machines are quickly identified, evaluated, and resolved. Since many facilities may already have a process to maintain their machines, this solution allows for the program and resources to be optimised for faster and better results.

Increased productivity

As we’ve established above, when something goes wrong, it wastes time, money, and resources. There could even be injuries or property and environmental damage that hurts the business. But staff training on using a condition monitoring system for enacting predictive maintenance can lead to a healthy and efficient facility. Educating operators about monitoring techniques and how to flag data indicative of a machine failure could resolve an issue before it causes a major shutdown.

Stable, experienced support staff

Finding top talent in today’s environment is also a major hurdle for many manufacturers. Companies that do not have condition monitoring solutions tend to be very reactive, spending more money than necessary on diagnostics and solutions while incurring high costs of unplanned downtime. Working with sensors and a reliability partner can ensure uninterrupted support.

24/7 risk mitigation

In today’s demanding manufacturing environments, technicians often wear multiple hats and can’t focus their undivided attention on monitoring equipment. For critical equipment and processes, having installed sensors for condition monitoring and a reliability partner at the ready ensures that unplanned events are not the norm. All the data is transferred in real time, where experts review it. In fact, most companies will find that the lead time for response will be reduced by approximately 50%.

There is no one right way to maintain your equipment, but with advancements in technology, it’s clear that predictive maintenance can save time, money and resources. Don’t get stuck waiting for a machine to break. Take control and have a pulse on your machines’ health with condition monitoring through sensors and a reliability partner.