Piping design for food and beverage applications

Several factors need to be considered when designing the piping element of a pumping system, and in the food and beverage sector, there are specific considerations related to hygiene. Chris Callander outlines some best practices in piping design to meet stringent regulatory standards and achieve high-quality production outcomes.

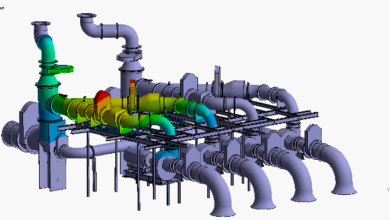

The piping design for a pumping system to be used in the food and beverage industry is critical for maintaining product integrity, ensuring safety, and optimising operational efficiency. Let’s look at several key areas which include material selection and standards, hydraulic considerations, layout optimisation, flexibility and monitoring.

Material selection

In many food and beverage applications, stainless steel is preferred for its corrosion resistance, ease of cleaning, and non-reactive properties, which can be crucial for maintaining product purity.

Food-grade plastics may be used in specific scenarios where flexibility and corrosion resistance are critical, but with caution regarding wear and chemical compatibility.

Establishing which standards are relevant to your sector and application is important. These will often affect material selection and other aspects of system design. For example, 3-A Sanitary Standards and EHEDG Guidelines ensure equipment design promotes hygiene and is easy to clean and sterilise. While ASME BPE guides the design of bioprocessing equipment, which is applicable in many food and beverage processes.

Hydraulic considerations

Correct pump and pipe sizing avoids issues like cavitation and excessive wear. The design of a system should employ hydraulic calculations to match the pump capacity with system requirements, considering factors such as fluid viscosity, density, and flow rate.

Maintaining optimal flow velocity helps to prevent sedimentation in low-velocity areas and erosion in high-velocity sections. Recommended velocities vary by application but typically range between 1.5 to 3m/sec.

Layout optimisation

Incorporating straight runs before and after critical components helps to reduce turbulence and facilitate easier maintenance. In addition, the layout should be designed to allow easy access to all equipment and valves for cleaning, maintenance, and inspection.

Sloping piping correctly is also important to promote complete drainage, a critical aspect in avoiding bacterial growth and cross-contamination.

Integration of cleaning and sterilisation systems

Piping should be designed with Clean-In-Place (CIP) systems in mind, ensuring that all parts of the system are accessible to cleaning solutions without dismantling. Features like spray balls for tanks and appropriate connections for CIP systems to circulate effectively should also be included in the design.

Ensuring flexibility and scalability

Adopting a modular design approach allows for easy expansion or reconfiguration of the piping system as production needs evolve. While using standardised components helps to facilitate quick changes and minimise downtime.

Monitoring and Quality Assurance

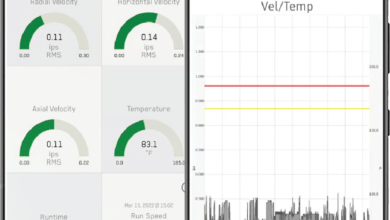

Integrating sensors and flow meters for real-time monitoring of pressure, temperature, and flow rates makes it possible to ensure the system operates within specified parameters.

While implementing automation solutions for critical control points can enhance precision and reliability in product quality.

Conclusion

Designing a piping system for food and beverage processing is a complex task that demands a strategic approach to material selection, layout optimisation, and system integration. I have only been able to give the briefest overview here, and I would recommend talking to a specialist, such as your pump supplier, before starting the system design process if you are unsure of any of the areas mentioned above.

But, by adhering to industry standards and incorporating best practices in hydraulic design, cleaning, and monitoring, businesses can achieve a highly efficient, safe, and scalable pumping systems. This not only ensures the quality and safety of food and beverage products but also enhances operational efficiency and sustainability in the long run.