Supporting hydrogen production for long-term decarbonisation strategies

Next to the metal industry, the basic chemicals industry is the highest energy consuming industry in Germany. Until now, its energy demand has primarily been covered by fossil raw materials, which are anticipated to be at least partly replaced by green hydrogen in the future. In this changeover, pumps and valves play a decisive role, as KSB explains.

Apart from solar power and wind energy, hydrogen is a key energy source in almost all industries. Green hydrogen has more uses than just serving to drive vehicles and store renewable energy. In refineries, previously grey hydrogen used for desulphurising the pre-products of petrol and diesel oil is to be replaced at least partly by green hydrogen. In pilot projects in the steel industry, green hydrogen is already being used for the direct reduction of iron ore as an alternative to the furnace process with high greenhouse gas emissions. The cement, glass and ceramics industries are also looking for new ways of converting their processes into a CO2-neutral production.

However, this change will only be successful if an efficient and economical hydrogen industry is established, including production, import, transport, storage and conversion. This may sound good on paper, but in reality, the details to be considered for decarbonisation strategies are manifold.

Pumps for today’s and tomorrow’s processes

KSB has been involved in hydrogen developments for many years. Both its valve and pump portfolios already comprise a broad range of products that can be used in all stages of the hydrogen value creation chain.

Christof Lindner, who is responsible for hydrogen technology at KSB’s General Industry Market Area, explained the current situation: “A challenge when implementing hydrogen projects is that detailed requirements for the components used still vary greatly, for instance, the materials and the surface qualities.”

With regard to conversion processes (e.g. ammonia) and blue hydrogen production processes based on fossil fuels (SMR, ATR, and CCS), KSB’s pumps and valves have been operating for many decades. The same also applies to valves for chloralkali electrolysis, where its diaphragm and butterfly valves have long been popular choices. Despite this background, Lindner is aware that: “Many questions, such as hydraulic balancing or the duty cycle of pumps in the different hydrogen processes can only be clarified when the development is more advanced.”

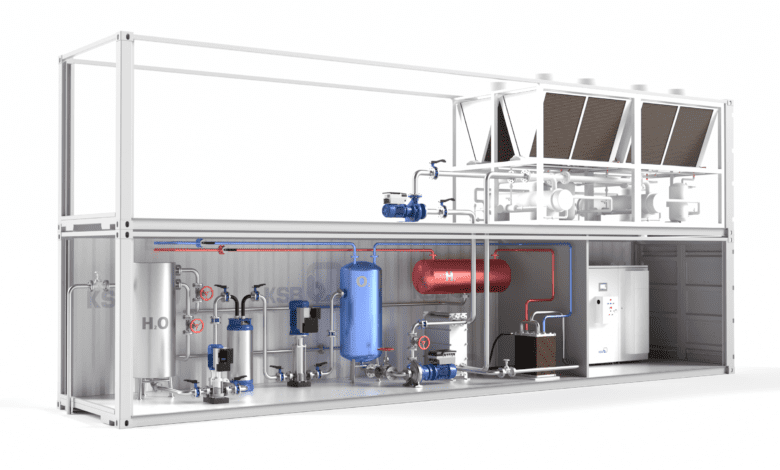

Another issue that needs to be addressed is the system size. Currently, electrolysers are usually modular designs, which raises the question of what will be more advantageous from an energy point of view in the future. Having each electrolyser fitted with its own cooling system or having several parallel electrolysers fitted with a common cooling system, which requires more powerful pumps? Looking to the future, what will be more popular, container solutions or large-scale projects? This also directly impacts on the selection of pumps and valves.

Container solutions would have flow rates of about 10 m³/hr, but large projects (studies only at this stage) may exceed 800m³/hr. Likewise, the operating pressure may range from 6 to 40 bar. Larger, modular systems may also have higher control requirements for an optimum interaction of components, requiring variable speed pumps and control valves.

“A supplier not only needs a broad product programme to cover a wide field of applications, but also detailed knowledge on systems engineering, duty cycles, materials and energy efficiency,” said Lindner. This is especially relevant since several different technologies for green hydrogen production are available or emerging.

KSB’s resources cover all main technologies of green hydrogen production, whether it is alkaline electrolysis (AEL), proton exchange membrane electrolysis (PEM) or future technologies, such as anion exchange membrane electrolysis (AEM) or hightemperature electrolysis (HTEL).

Pumps and valves for alkaline electrolysis

Known for more than a century, alkaline electrolysis is certainly among the most highly developed technologies. However, its potential for reducing costs is limited. “Since its operation is still more durable and reliable than PEM, operational disadvantages such as the hazardous fluid or the low flexibility regarding a change in load conditions are accepted,” explained Lindner. Diaphragm valves and seal-less pumps that contribute to making the processes safer are represented by the SISTO-20 or SISTO-16s type series and the ISORIA or the KE type series butterfly valves that are made of corrosion-resistant material or coated accordingly. SISTO diaphragm valves, for example, are designed with a completely enclosed and spiral-supported TFM diaphragm, which is provided with flexibility by an EPDM diaphragm fitted at its rear. The diffusion-tight TFM and a PVDF barrier foil in-between the diaphragms reduce gas diffusion, thus protecting the environment and the valve interiors. Valves needed for cryogenic applications, such as the subsequent transport, are covered by the KSB DANAIS type series. Experience with valves for liquid hydrogen (-253°C) results from optimising the Ariane rocket programme in test facilities.

Among the pumps tried and tested in alkaline electrolysis is the Magnochem horizontal volute casing pump with a magnetic drive. The standardised chemical pump is available in close-coupled design or back pull-out design. “This seal-less pump has been used for many years in industries whenever toxic, explosive or valuable fluids have to be pumped. It is the ideal match for hydrogen technology,” Lindner added. With its magnetic drive, the pump is hermetically sealed, thereby averting the risk of leakage. This plays a major part in alkaline electrolysis, where caustic potash is pumped and crystallises in contact with the atmosphere. The pump’s close-coupled design makes it suitable for tight installation spaces.

Compliant with ISO 5199, the Magnochem pump, with its broad range of hydraulic sizes, materials and magnetic drives, offers a large number of technically feasible variants. This makes it a good match for the most diverse of tasks in hydrogen production, and the user receives a pump with maximum safety, reliability and economic efficiency.

Another pump type suitable for hydrogen production is the multi-stage, vertical high-pressure centrifugal pump. Typically used for water treatment and pressure generation, it is designed for up to 40 bar and is very flexible, having a number of stages and the option of speed control. The compact design is a perfect match for installation in tight spaces in container solutions. Even at low flow rates it can generate high pressures.

It should be noted that hydrogen technology involves more than just hydrogen production. A key process to be considered is the cooling water supply. Etabloc /Etaline type pumps, or ISORIA and SISTO-20 valves, are frequently employed for cooling heat exchangers. Using PumpDrive variable speed systems to deliver maximum energy efficiency, the pumps’ vertical installation and in-line design mean they are very compact.

PEM electrolysis is ready to take off

PEM electrolysis is a much more recent technology. Its benefits are safety, ease of use and high flexibility at changing loads. Compared to alkaline electrolysis, this technology offers a lot of potential for technical developments and cost savings, and it does not require the use of any risky chemicals. The toxic electrolyte aside, the application conditions for pumps are similar to those of alkaline electrolysis. The new technology is particularly interesting when looking at the aspect of hydrogen production from renewable energy sources becoming fit for mass production in the future. KSB is contributing to these developments by providing diaphragm valves, butterfly valves, and various pumps for pilot systems.

Future tasks

Experts see the tasks of future technologies, such as anion exchange membrane electrolysis (AEM) or high-temperature electrolysis (HTE), as being a particular challenge in accommodating the high temperatures that place demanding requirements on materials. Regardless of the method used in the future and what system size will prove more suitable, Lindner sees KSB’s portfolio of valves and pumps providing the technologies that deliver the best efficiency as well as maximum safety and reliability that these future technologies require. chevron-circle-right