Sealing solutions deliver significant savings for pulp mill

AESSEAL explains how, by using the company’s dual cartridge seals combined with water management systems to eliminate over 61 million gallons of water from 26 evaporator pumps, a pulp mill’s evaporator steam use was reduced by 103,000klbs a year.

A northern bleached softwood kraft (NBSK) pulp mill located in western Canada has two production lines with a production capacity of 365,000 tonnes of pulp per year. The facility produces high quality kraft pulps made from custom blends of Douglas fir, western hemlock, balsam fir, interior SPF and western red cedar. The diverse pulp blends are sold in Asia, Europe, North America, and Latin America to customers who make commodity and specialised grades of paper as well as non-paper products.

THE PROBLEM

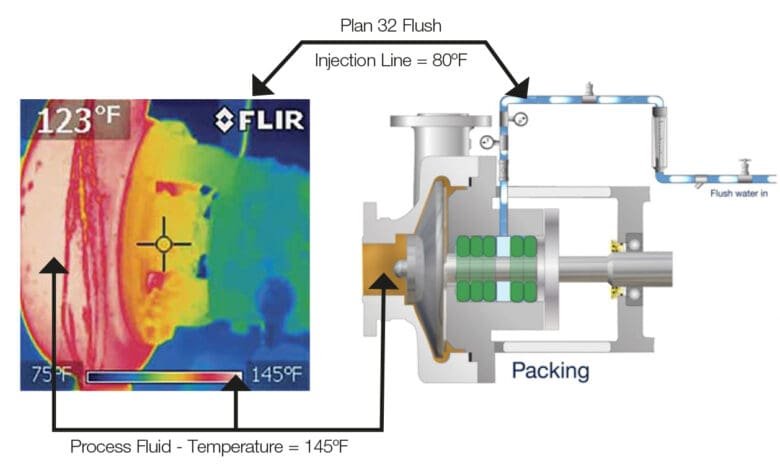

The centrifugal pumps transferring black liquor through the evaporator and concentrator area of the mill for black liquor solids concentration were sealed using conventional packing. This was the root cause of internal and external mill water leakage, resulting in excessive steam use, elevated energy costs, operational inefficiencies, and high water consumption.

Packing needs to press tightly against the rotating shaft on a pump to achieve the most efficient seal. The resulting friction means the packing must be lubricated with high volumes of flush water to prevent overheating. It also gradually wears away the pump shaft sleeve, increasing black liquor dilution rates and external leakage. This leads to maintenance expenditures that can be avoided with mechanical seals and support systems.

The thermal efficiency of recovery boilers is improved by using black liquor with high solids concentration. Black liquor concentrators are designed to increase the solids content of black liquor to 65 – 80% before combustion in a recovery boiler. An increase in solids content means that less water needs to be evaporated in the recovery boiler. This can increase the efficiency of steam generation significantly.

The inefficient packing in the pumps was allowing an average of 3.75gpm of the flush water to enter into the black liquor stream, diluting the product at each pump. This ingress of cool water resulted in an excessive amount of water having to be evaporated before the liquor could be concentrated enough for firing in the recovery boiler, and further recausticising into white liquor to cook wood chips in multiple digesters.

The amount of steam required to evaporate the diluted black liquor was calculated at roughly 12.1klb of 60psi steam every hour – an annual total of 103,000klbs – which incurred excessively high energy costs. Maintenance personnel had to make frequent adjustments to the packing to minimise the leakage of water and hot liquor, which at temperatures of up to 150°C, raised serious health and safety concerns. The leaking fluid also risked damaging bearing frames and bases, impacting asset reliability. The packing on the pumps had to be changed every six to 12 months to prevent premature failure.

The evaporator area in the power and recovery plant of a kraft pulp mill is one of the most critical areas of the plant. The mill cannot function if the area is shut down, and if the throughput of the evaporators is limited, production losses can occur. Consequently, running it to its optimum efficiency is essential.

THE SOLUTION

AESSEAL worked with the client to survey the assets in the evaporator area and identified 26 pumps where eliminating flush water was most critical. It recommended replacing the packing on each pump with a CDSATM dual cartridge seal and a 25l SW2TM water management system.

Rather than carry out the work in stages, as is typical for such large conversion projects, the plant scheduled work on all 26 pumps to be completed during a two-week maintenance shutdown. This was to avoid any unnecessary disruption to operations in this vitally important area. AESSEAL Canada worked very closely with the plant’s maintenance and engineering teams through the pump refurbishment process and commissioning.

The API Plan 53A supply support system supplies clean, cool water at a constant pressure to the barrier space between the double seals at a pressure higher than the product pressure, ensuring that a consistent, stable and clean fluid film keeps the seal faces cool and lubricated. The water is constantly recycled, flowing between the inboard and outboard seal faces in a continuous loop and reducing leakage to the absolute minimum – roughly one teaspoonful a day, in the form of vapour.

Based on recordings carried out before and after the installation, dilution of the black liquor stream has been reduced by 97.9 gallons of water per minute. Evaporating this volume of water was calculated to require 12.12klb of 60psi steam per hour – totalling around 103,000klbs a year.

The steam saved was subsequently diverted to the mill’s turbo generator to provide additional carbon-neutral electrical power for onsite needs and for the North American grid.

THE SAVINGS

With the ROI on the entire project’s costs achieved in less than one year, it is estimated that to date, the mill has saved CA$9.7m (£6.1m), conserved almost 500 million gallons of water and reduced its carbon footprint by 45,000 tonnes of CO2e (carbon dioxide equivalent) over eight years by adopting AESSEAL dual cartridge seals combined with water management systems. The total repeatable annual cost savings due to reduced energy and water usage alone amount to just under CA$1 million (£628,000) per year. There is also an enormous 61-million-gallon reduction of water use every year – enough to provide the total water needs of 2000 people. The mean time between failures (MTBF) has improved from one year to five or more years. While lowering the company’s carbon footprint is worth an additional CA$234,000 (£145,000) annually, and this is set to rise to almost CA$1 million (£628,000) annually by 2030.