Condition monitoring solution detects rotational direction

Flemming Munk, Chief Engineer, Condition Monitoring at Grundfos Water Utility, provides insight into what he believes is an exciting new condition monitoring solution developed by Danish start-up, EWA sensors.

As a pump manufacturing company, Grundfos is approached by companies offering condition monitoring solutions for our pump systems on a weekly basis. The business potential of condition monitoring and customer service agreements are huge, and this has triggered an explosion in the number of companies offering Condition Monitoring Solutions (CMS) that can detect every possible machine fault in rotating machinery. As a customer, it can be difficult to navigate between all the CMS offerings, but a simple and fundamental question is: “Can your system detect the rotational direction of my machine?”.

For a rotating machine, the RPM and direction of rotation are fundamental parameters, and if the CMS system is not able to measure these two parameters, the foundation for further detection of imbalance, bearing failures, gear issues etc., becomes a little frivolous. It is a good measure of the insight and understanding of rotational machinery that the CMS provides, and will flag, a ‘wannabe’ CMS system. A good CMS takes many years to build and demands deep technical knowledge about applications, signal analysis and sensor design. In this regard another interesting measure is the ISO 18436 certification level of developers. No certification is for me a clear flag, that they are in it for the quick win – I would never consider adopting such a system.

However, one system has recently caught my attention – the solution from EWA Sensors. EWA stands for Early Warning Analytics and it is a small start-up company from Denmark. The system measures a range of parameters including RPM, rotational direction, imbalance, cavitation and gear issues, and the founder is ISO 18436 Cat-IV certified from both Möbius Institute and Technical Associated from Charlotte PO – so the company passed the acceptance test .

The EWA platform

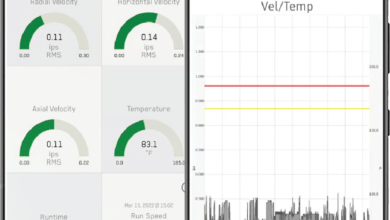

The founder of EWA sensor has chosen to follow a different approach to what we normally see in this age of IoT devices. The sensor is a pure edge device with no cloud support and no human-in-the loop. All analytics are performed by the sensor, using a built-in Cortex-M7 microcontroller. It is a wired sensor for Modbus communication and with 24VDC power. All parameters are accessible to the customer through Modbus/SCADA. The sensor measures vibration, magnetic field and temperature and applies a combination of vibration signature analysis and motor current signature analysis, which make the parameter set very robust. It is a true plug-and-play platform with no pre-configuration of parameters, like motor pole pairs – the sensor will find the number by analysis. The sensor is designed as a pressure capsule and can be used in both dry installed and submerged (10m) applications. For water utility applications, there is generally no benefit in using wireless IoT – if we are going to use 50m of cable to the gateway, it is not a problem to use an additional 4m to the sensor. The sensor is equipped with four LEDs – for power, direction of rotation, Modbus communication and alarm/machine health.

The sensor calculates a large number of condition monitoring parameters, but I want to focus on two that are new to the market.

Rotational direction

Many CMS seek to provide very high-level conclusions in relation to alignment, cavitation, bearing condition etc., but miss fundamental low-level operational parameters. When we are talking about condition monitoring for rotating machinery, it is important to know ‘is my machine rotating or is it standing still’ and if it is rotating ‘what is the rotation direction’ – counter clockwise (CCW – negative RPM) or clockwise (CW – positive RPM). Many CMS cannot tell if a machine really is rotating as vibration on the line frequency is not a clear sign of an operating machine, it could be the adjacent machine. The EWA sensor measures the rotational direction of the motor every second and provides this information both through an LED on the sensor with CW (green), CCW (red) and no rotation (no light) and outputs it as a Modbus parameter. It sounds very simple, but I don’t see this feature very often. It is an important parameter, as rotational direction can be shifted after a service, if the power cables are incorrectly reconnected by mistake. Numerous real-life cases exist with sewage pumps that have been operating for years in the wrong direction, without anybody noticing anything other than lower performance. If a CMS is not able to measure rotational direction, it is not a condition monitoring system for rotating machinery, but a condition monitoring system for vibrating machinery.

As a side-effect of measuring the direction of rotation, the EWA sensor also detects whether the installation is a horizontal or vertical machine.

High resolution RPM

The rotation speed of the pump impeller is often regarded as a fixed number, but nothing could be more misleading. RPM is a time function, and the RPM fluctuation of a pump impeller contains a lot of information about the pump loading and the liquid homogeneity – this will be evidenced when the RPM is estimated with high time resolution, like every second.

The EWA sensor estimates both the RPM of the rotor rotation and the magnetic field rotations, and also the number motor pole pairs. RPM estimation from a pure vibration spectrum can be very difficult in environments with simultaneously operating machines (like a booster station), but this combination of vibrations signature analysis and motor current signature analysis makes the RPM estimation very robust. Figure 1 shows the magnetic (blue) and vibration (orange) RPM measurements from a sewage pump performing deragging to reduce clogging.

It is clear that the deragging is successful, as the fluctuation of the impeller RPM is reduced (the orange curve) after deragging.

As the sensor also measures the pump’s direction of rotation, the RPM is a signed variable. This is illustrated in Figure 2.

From the RPM measurement it is also clear that every operation cycle is ended by a short reverse rotation – following the pump manufacturer’s requirements.

Another interesting feature of the EWA sensor, that I have not seen from other CMS providers, is its submerged robustness. The sensor has been pressure tested to 30m and approved to 10m. We are currently testing this with our mixer program, and the results look very promising.

The sensor provides us with a depth of insight into an application that is normally not accessible. Information about slip, RPM, 3D RMS, gear mesh frequency, etc. and corresponding baselines are now calculated with one second intervals, providing us with insights that we did not have before. This is valuable for both the pump manufacturer (in terms of pump performance and design considerations) and for the customer (to indicate machine health and process performance).

Conclusion

The EWA Sensor is offered as a one-time purchase with no subscription fee, which makes the economic part simple. It is targeting customers with their own SCADA or cloud system for the display of parameters, baseline data and alarm handling. The sensor is glued onto the outside of the pump unit, or could be built into the pump, perhaps in the terminal box. The approach is generic and will work on machines with an electric motor with no specific brand required.

All in all, it is an innovative condition monitoring solution that is different from what is currently being offered by the CMS market. chevron-circle-right