Twenty six ways to break a pump

Over 40 years of manufacturing pumps that process harsh and

acidic chemicals, Crest Pumps has seen more than its fair share of pumps that have been broken due to mismanagement and misinformation. Here, the company outlines 26 ways to break a pump so you can see if your business is making the same mistakes and take avoiding action.

Relying on reactive maintenance: Too often, pump maintenance is overlooked or forgotten within the maintenance procedures, only carrying out reactive maintenance if the pumps fail, leading to longer process downtime, pump instability and expensive repairs. Instead, schedule biannually or quarterly pump maintenance, including inlet cleaning, corrosion inspection, vibration monitoring and heat maintenance, at the very least to ensure that cavitation or bearing wear is avoided.

Improper bearing fitting: When a bearing is replaced, or the shaft is cleaned, just a tiny fraction of the material on the surface is removed. Over time, a little adds up to a lot and can significantly affect the bearing clearance on the shaft. When this happens, expect the bearings to spin within the housing or on the shaft.

The wrong seals or seal material: Lack of knowledge accounts for the majority of mechanical seal failures. Incorrect mechanical seal installation can lead to seal face damage, heat escalation and ultimately pump failure. Discuss the type of chemicals you are processing and the type of mechanical seal you need with the pump manufacturer.

Hard-starting: A pump should be eased into pumping with a soft start. With a hard start, the pump tries to pump liquid as soon as it powers on. The pressure inside the pump causes the shaft to deflect towards the low-pressure side, causing the shaft to contact the casing. The misalignment will then cause seal failure. Remember to keep the suction valve wide open.

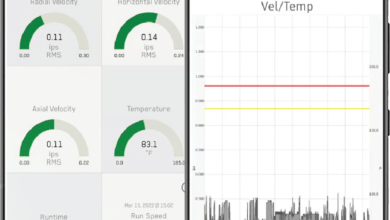

Not detecting vibration: Vibration can signal that the pump is seriously failing in its process. Vibration can damage wear rings, bushings, impellers and the bolts connecting the pump and motor. Vibration leads to the shortening of the pump’s life by over three-quarters, so it is imperative that if excessive vibration occurs, your engineers take the necessary steps to find the root of the problem.

Improper starting: This can lead the motor to trip and the shaft to twist, causing orbital movement directly related to internal parts contact, seal failure and shortening of the bearing life.

Pumping with a bent shaft can cause vibration, leading to the shortening of the pump’s lifespan. A bent shaft can result from either operating away from the best efficiency point (BEP) or pumping solids in a pump that cannot effectively deal with them.

Solids trapped in the seal housing: When the processed liquid and abrasives get stuck in the seal housing and aren’t properly flushed out, expect a shortened seal life.

Pump imbalance: This can create structural problems, reduced bearing life, increased vibration and reduced machine life. Vibration is the second biggest cause of pump failure and the largest cause of vibration is pump imbalance.

Using the incorrect tools for installation or repair: This includes practices such as using a hammer to install couplings onto shafts or pipe wrenches for anything other than pipes. Pumps are delicate machines that can crack if struck with a hammer.

Plugged vanes or balance holes: These are caused by blockages from solids that have been pulled into the pump that are too large for the pump capacity. Plugged vanes decrease performance, efficiency, priming issues, impeller imbalance and high vibration, resulting in seal damage.

Incorrect wear rings: A wear ring separates the high-pressure zones of the pump from the low-pressure zones. When clearances open up, the pump experiences increased slippage, and the high-pressure liquid seeps back into the low-pressure areas, causing a loss in efficiency. When clearances are too tight, on the other hand, the wear ring will cause galling and seizing of the pump.

Entrained vapour: This can be caused by a number of factors: A vortex in the tank, insufficient water source, steam injection or incorrect NPSH conditions. Entrained vapour causes performance loss, wear to the impeller and cutwater, and dry running of the seal due to vapour between the faces.

Pipe strain: This is unwanted pressure or movement in the piping system, causing the pipes to put strain on the pump. It can be caused by improper design or installation, thermal or pressure changes, the lack of or improper design and placement of pipe supports, or process changes.

The likelihood is that the discharge piping is incorrectly or inaccurately installed, creating stress on the pump casing that will detrimentally affect the reliable life of the seal and bearing.

Too little lubricant: This can cause premature bearing failure, causing the bearings to seize and fail the pump.

Too much lubricant: This can also cause problems by retaining heat inside the bearing, causing oil leakages and shortening the pump’s life.

Incorrectly adjusting the impeller: This can lead to increased slippage in the pump, creating more turbulence inside the pump, lowering efficiency and increasing pressure inside the stuffing box.

Poor piping connected to a pump: Like pipe strain, this can cause a pump to underperform. Pipework designed with an immediate invert, bend or ‘U’, can cause trapped air in the system. Designs with an immediate 90° bend before the pump can cause turbulence inside the pump. Both result in suction and cavitational problems for the pump.

Using the wrong sized impeller for the pump: This causes the pump to produce too much or too little flow, running away from the BEP. If the impeller is too big, the pump motor has to work harder to pump the fluid, eventually causing it to burn out and dramatically shortening the pump’s life. If the impeller is too small, it is unlikely to generate enough flow or head. Again, it’s important to talk to the pump engineers or arrange a site visit to get down to the route of the problem and correctly size the impeller to the operation.

Operating too far to the right of the ‘curve’: Pumps are designed to run at their most efficient point, the BEP, which is shown on a pump’s performance curve. This allows for safe pumping at the most energy-efficient point of the duty required. Running outside of the BEP can reduce efficiency and cause a strained operation on the pump. This can quickly lead to excess re-circulation, radial loss, vibration, high seal temperature and vastly lower efficiency.

Improper alignment: This is a serious cause of pump failure. Up to 50% of damage to rotating machinery is directly related to pump misalignment. This means increased vibration, premature seal and bearing failures and increased power consumption. Excessive misalignment can even cause breakage of mounts or pump casings.

It is important to check the alignment of the pump before it is fully operational. Two types of misalignment should be checked for: angular and parallel. At Crest Pumps, we deliver pumps mounted on a base plate and pre-aligned at the factory to ensure that the pump stays properly aligned and protected.

Pumping solids or abrasives: In a pump not set to deal with viscous media or solids can clog and break the pump. If the pump is improperly selected for the application, expect to see a shortened life on nearly all components (casing, impeller, stuffing box, etc.). Users should consult with their pump manufacturer, as many pumps can be designed to fit the exact specifications of an application.

The wrong chemicals for a pump: Pumps are designed for specific chemicals using the most efficient, safe and reliable materials for the desired application. If the pump is then used for a chemical that the pump was not built for, the corrosive properties of the new application can erode the insides of the pump, causing immediate pump failure and a potential spillage, disrupting the process, production line and the area around the pump if there is a leakage.

Operation at shut off: When a discharge valve is partially or entirely closed to manually control the flow, it causes 100% of the input energy to be destructive. This leads very quickly to a build up of pressure and pump failure. Consult the pump manufacturer on how to control or get the optimal head, flow or pressure.

Mechanical seal installation error: Improperly installing the mechanical seal will cause damage to the elastomers (O-rings) as well as a wide variety of other issues. Mechanical seals can be very sensitive as the faces are incredibly flat. Even a small amount of dirt or oil (even from fingerprints) can cause the faces to misalign.

Running dry: Both mechanical seal and magnetic drive centrifugal pumps can suffer from running dry if the pump hasn’t been designed to combat it.

Allowing a pump to dry run can lead to catastrophic pump failure in some circumstances. For a mechanical seal pump, running dry could lead to pump cavitation and, therefore, seal damage. The mechanical seal could also experience thermal shock and, under the right conditions, could shatter within 30 seconds.

With a mag-drive pump, the bearings and shaft can rise in temperature due to the absence of liquid lubrication and subsequently melt the plastic casing.