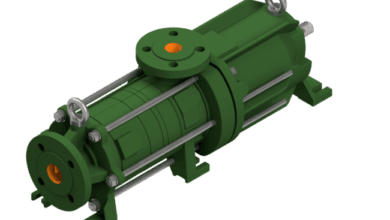

New submersible motor pumps with axial propeller

KSB SE & Co. KGaA is launching a new generation of submersible motor pumps with axial propellers.

The AmaCan P type series is designed to transport large volumes of municipal or industrial water as well as wastewater from stormwater, drainage and irrigation pumping stations. When selected with optional corrosion-resistant and abrasion-resistant materials, the type series can also be used in water pollution and flood control or in seawater aquaculture systems.

Different blade angles serve to achieve the exact operating points required by the customer. Priorities set by the developers were a high operating reliability as well as high hydraulic efficiencies. This is where the newly developed impellers with their three blades and high free passage come into play.

The design of the pump sets has been shaped by the KSB Group’s decades of experience with this type of pump. The pump’s self-centring, non-positive seating in the discharge tube, sealed by an O-ring, makes it easy to install and remove. This means no anchoring or anti-rotation elements are needed.

Selecting drives with a low energy consumption is important for submersible motor pumps, too. This is why electric motors with efficiency levels comparable to those of standardised motors to IEC 60034-30 are available, either as asynchronous motors with IE3 Premium Efficiency or as synchronous permanent magnet motors with IE4 Super Premium Efficiency.

Two bi-directional mechanical seals reliably prevent water ingress into the motor space. A chamber filled with environmentally friendly oil ensures cooling and lubrication of the mechanical seals even when gas-laden fluids have to be pumped. Generously dimensioned ball bearings sealed for life support the stainless-steel shaft.

Integrated, intelligent sensor monitoring detects any vibrations or leakages and measures the temperature of the bearings and the motor. It provides continuous supervision of operation and early detection of malfunctions, as well as the option of predictive maintenance.

Special focus was further placed on the design of the cable gland. Individual conductors stripped, tinned and sealed in resin ensure that the cable gland is absolutely watertight. Even in the event of damage to the cable sheath or the insulation, thanks to this design, the pump is protected against short circuits. To ensure that the pumps can be easily dismantled even after years of operation under tough conditions, all wetted screwed connections are made of high-grade stainless steel.