New machining centre reinforces UK supply chain and enhances casing production at Apex Pumps

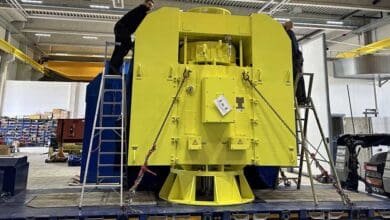

Apex Pumps has made its largest single investment in plant and machinery to date with the installation of a Mazak HCN-5000 NEO horizontal machining centre at its UK facility.

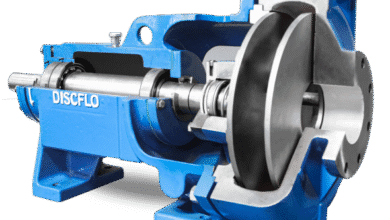

The high-speed, four-axis machining centre, which features a twin-pallet system, will be used primarily for the production of pump casings supplied by UK foundries. The investment is aimed at increasing capacity, improving consistency, and enabling shorter, more reliable lead times for customers operating in demanding industrial environments.

Managing director Andrew Simpson said the decision was driven by a need to strengthen supply chain resilience and gain tighter control over production processes.

Fewer operations, improved tolerances

The new machining centre is expected to simplify the production of pump casings significantly. Previously, each casing required an eight-operation process spread across three separate machines. The new equipment enables completion in just two operations.

By reducing the number of set-ups, Apex Pumps intends to minimise the cumulative tolerance variations that typically occur when components are transferred between machines.

“We are going from an eight-operation process to a two-operation process, so you do not have the same stack-up of tolerances where you are going from set-up to set-up,” Andrew said. “From a tolerance point of view, it will be tighter, and from a time-to-produce point of view, it is quicker.”

The machining centre’s twin-pallet design is also expected to support higher machine utilisation, as operators can prepare the next component while the current one is being machined – keeping downtime to a minimum.

Faster turnaround and increased flexibility

Alongside productivity gains, the new capability is intended to enable a more agile approach to supply and configuration. By stocking unmachined casings and carrying out final machining at the point of order, Apex Pumps aims to improve product availability and offer greater flexibility across different flange specifications.

“We can keep unmachined parts on the shelf and then do just-in-time machining,” Andrew added. “If it is an American flange specification, we can do an American flange spec, or if it is European pipework spec, we can customise it. Before, we would either have to hold both on the shelf, or order the alternative configuration on a longer lead time.”

Capacity for high-alloy materials

The machining centre is expected to support a broader range of casing materials, including stainless steel, duplex, nickel alloys, and titanium. Initial efforts are focused on reshoring stainless steel production, with additional developments planned as Apex Pumps continues to expand its manufacturing capabilities.

“Ultimately, we want to keep hold of vertical integration where others might subcontract it,” Andrew said. “This makes it possible to do more in-house. We would not be able to do it using the eight-operation method.”

The new machining centre has completed commissioning and is currently being integrated into full production, supported by Mazak application specialists and internal training programmes. For Apex Pumps’ customers, the primary benefits are improved stock availability, shorter delivery times, enhanced tolerance control, and a more robust domestic supply chain.