New clean-in-place enabled pump for hygienic, energy-efficient and simplified cleaning processes

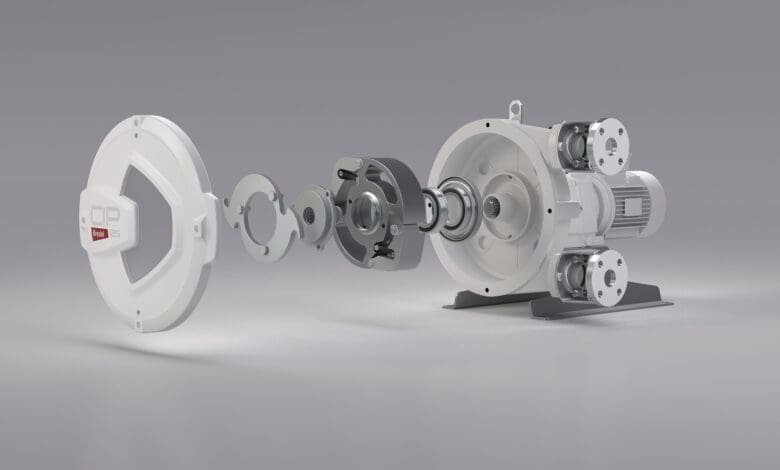

Bredel hose pumps, part of Watson-Marlow Fluid Technology Solutions, has launched the Bredel CIP pump for sanitary and hygienic processes that require optimal efficiency and regular clean-in-place.

In food and beverage, pharmaceutical and cosmetics production, lengthy downtime for cleaning equipment and batch contamination result in higher costs. However, a pump that supports clean-in-place (CIP) without bypassing or disassembly minimises production downtime and avoids spoilt product due to contamination.

Watson-Marlow Fluid Technology Solutions (WMFTS) has designed the CIP pump with a new rotor to enable companies to achieve the CIP cleaning velocity requirements of greater than 2m per second.

Automatic retractable shoes for cleaning the pump element inside are specifically designed for CIP processes to allow the pump and the rest of the system downstream to be cleaned at the correct fluid velocity. By retracting the shoes during cleaning, hose compressions at high temperatures are eliminated, thereby extending hose life and reducing the costs of replacement hoses.

The new CIP pump is available in sizes 20 (600 l/h), 25 (1800 l/h) and 32 (3200 l/h).

Existing customers can easily upgrade their pump rotor to the CIP variant in situ with clear instructions, without removing the pump from the process line and experiencing downtime.

Bredel calculates that users of the CIP pump can achieve significant energy savings, leading to lower carbon emissions and a reduced environmental footprint. For example, a brewery operating 24/7 with four one-hour cleaning cycles a day can now reverse the CIP pump to retract the shoes and turn off the pump during the cleaning process. This saves the brewery four hours of power for a pump that runs during the CIP cycle and therefore reduces energy consumption by 16% or 1,460 hours annually.

The Bredel CIP pump is compliant with food-safety standards (FDA, EC1935, and 3A).

Grace Madden, Bredel Product Manager, said: “The Bredel CIP pump is the perfect choice for reliable, accurate and gentle pumping. It can easily handle delicate ingredients such as yeast, additives and abrasive filtration agents that cause significant wear in other pump technologies. The CIP pump will help increase your uptime and decrease maintenance costs.

“This hygienic and efficient pump is suitable for food and beverage companies, including a wide range of brewing applications as well as handling products like fruit puree.”