Improving pumping processes for phenol unloading

CDR Pumps explains how updating a solution for unloading hazardous chemicals is saving a performance additives manufacturer over £31,000 per year in reduced energy costs, and cutting carbon emissions by around 180 tonnes.

SI Group is a global specialist in the manufacture of performance additives. The company’s UK manufacturing facility, based in the Midlands, produces Phenol-based products and constantly looks to improve working practices, save energy, and minimise hazards. Moreover, it allocates resources to create and manage sophisticated, accurate and productive facilities that emphasise a no-waste, high-efficiency philosophy.

A review highlighted the process of unloading Phenolic from 26,000l capacity road tankers and moving it to bulk storage tanks for further processing. Phenol, also known as Carbolic Acid, Phenylic acid and Benzophenol, is an organic substance used in the production of many chemical compounds. This material is subject to the highest tier of COMAH (Control of Major Accidents Hazards) regulations and has a number of associated handling precautions due to its tendency to solidify at low temperatures, as well as its hazardous and flammable nature.

The issue

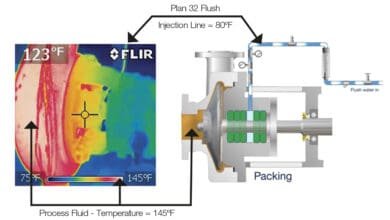

When the tanker unloading applications were installed, a selection of canned seal-less pumps had been fitted. These pumps were powered by 11kW ATEX-rated hazardous area electric motors. Since the product solidifies at lower temperatures, it was necessary to keep the pumps running constantly. The product is agitated, heat conductivity is spread throughout the entire feedstock, and the pump is kept warm and ‘moving’ to make sure small lubrication ports are clear.

The pump runs constantly for 180 days, totalling 4,320 hours, which consumed 99,360kWh of electricity each year. As there are four pumps, the total energy used annually is 397MWh.

Improving the process

The right unloading pump for this application was a magnetically driven centrifugal pump manufactured in stainless steel. Offering a zero-vapour loss, seal-less design means that the fluids and vapours have been contained and present no hazard to the immediate or wider environment or to the individuals working in that environment. Choosing a UTS-B mag drive pump also meant that the power needed to drive the pump could be significantly reduced, dropping from an 11kW motor to 5.5kW. This reduced the amount of energy being used by the solution whilst not compromising on loading and unloading times or compromising the operational effectiveness and lifespan of the pumps.

The solution also included heating jackets, which had been evaluated for their capacity to work with high pressure. This made it possible to harness the steam that was already accessible at the location and use it to maintain the necessary temperatures.

Reviewing and modifying the original operating procedures on site also meant that the UTS-B pumps could be safely switched off when not in use and still maintain efficiency thereby lowering energy consumption further still. This not only helped to conserve energy but also spared the components from unnecessary wear and tear. Additionally, it decreased the risks associated with operating process lines with liquids in them.

As a result, the new pumps operate for fewer than five hours a day, resulting in a yearly energy saving of 9,866 kWh per pump. The collective energy savings of installing four pumps is estimated to be 39MWh per year, with an annual financial benefit of over £31,600 at the current 2022/23 costs. As an additional benefit, CO2 emissions were reduced by 90%, amounting to a total of 186 tonnes of carbon reduction.