Flowmeters with Ethernet-APL awarded FieldComm Group certification

Following a comprehensive series of tests, FieldComm Group, the global standards-based organisation, has awarded Ethernet-APL physical-layer conformity certification to ABB’s first vortex flowmeter (VortexMaster FSV400) and swirl flowmeter (SwirlMaster FSS400) with Ethernet-APL communication interface. Vortex and Swirl flowmeters are among the most widely used flowmeters in process industries.

Ethernet-APL provides full Ethernet and TCP/IP connectivity in hazardous environments such as in chemical factories, oil and gas operations, and hydrogen plants. Up until now, the application of Ethernet

in most process industries has remained minimal due to concerns around safety, cost and limitations on cable length which have made it difficult to establish communication networks across large industrial facilities.

“For ABB, this certificate is an important milestone on our journey towards a fully

digitalised instrumentation and network- centric architecture,” said Tilo Merlin, Platform Manager for Instrumentation and Head of APL Development Program at ABB Measurement & Analytics. “Getting this certificate means we can be quick

in rolling out APL technology to other instruments based on the same platform. More specifically, Ethernet-APL-enabled pressure and temperature instrumentation is expected in 2025.”

“Product certification is key for assuring product quality and interoperability in industrial communication networks,” said Paul Sereiko, Director of Marketing and Product Strategy at FieldComm Group.

In June 2024, ABB announced that

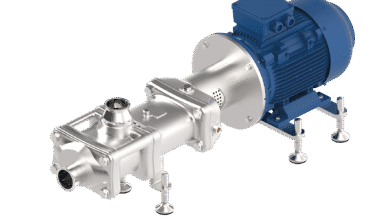

it was bringing the benefits of Ethernet communications to flow measurement with the integration of Ethernet-APL connectivity in its flowmeters for the first time. The

new FSS400 Swirl and FSV400 Vortex

flowmeters offer possibilities for simplified connectivity and high-speed collection and analysis of a wealth of process and diagnostic data in the field.

As a global standards-based organisation, FieldComm Group comprises leading process automation organisations, manufacturers, universities, and research organisations that work together to direct the development, incorporation, and implementation of new and overlapping technologies and serves as the source for FDI (Field Device Integration) technology.