Energy-efficient and durable slurry filter feed pump

By combining optimal hydraulics and wear-resistant materials in a pump replacement, Sulzer has helped a phosphate fertilizer producer to increase productivity with its AHLSTAR WPP end-suction single-stage pump.

Phosphoric acid is produced with a hemihydrate process, which is considered very severe for the rotating equipment installed in the reactor. The relatively high phosphoric acid concentration and impurities combined with the elevated reaction temperature create a very aggressive environment.

A slurry filter feed pump plays a very critical role in a phosphoric acid plant. A failure will directly impact the plant’s production rate, which is why robust and reliable equipment with the longest possible lifetime was considered to be of prime importance in this application.

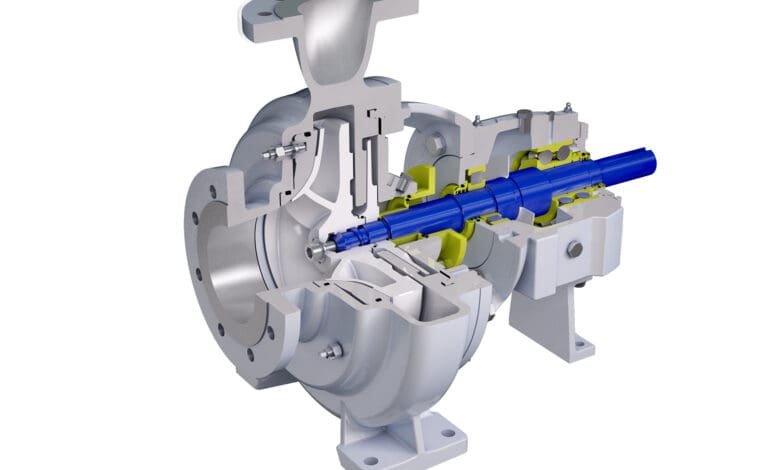

Sulzer selected an AHLSTAR WPP53-100 single-stage process pump for the site. The WPP pumps are designed to be extremely wear-resistant and especially suitable for abrasive and erosive industrial applications. The series offers a comprehensive material selection, and the pumps can be tailored to suit the most demanding industrial applications with accessories such as shaft sealing solutions and heavy-duty bearing units.

The previous pumps were made of a material that is very commonly used in phosphoric acid applications, CD4MCuN. This duplex stainless steel can give acceptable results in some applications of a dihydrate process, but it is not one of Sulzer’s solutions in a hemihydrate process. In this case, the company prefers a higher-grade alloy, 654 SMO. This material, classified as 6%Mo super austenitic stainless steel, has an excellent resistance to corrosion by hot acid with a high chlorides content. It is more and more commonly used in the phosphate industry because it combines a very good resistance to corrosion and better erosion resistance than some more common austenitic stainless steels.

The previous pump at the site was rotating at a speed of around 1,800 rpm, which was too high for this application. A pump with a low speed of rotation and a full-diameter impeller was required — an AHLSTAR WPP53-100 with a significantly bigger impeller diameter than the previous pump was selected. Although the head is fixed, a lower rotation speed contributes to reduced wear. Other features adding to the prolonged lifetime of the pump are the wear-resistant design of a semi-open impeller and a casing fitted with a front wear plate.

Due to the modular construction of the new AHLSTAR WPP, only worn parts of the pump must be replaced. In the earlier pumps, the lifetime of the parts subject to the highest erosion and corrosion was very short, between three and six months. Along with the pump replacement, the average lifetime of the parts was increased to 12 to 24 months, reducing the maintenance frequency by up to 75% from what it used to be.

Given the harsh operating conditions and the vast improvements compared to the former installation, the replacement is considered to be very successful. After a few years in operation, the pump has proven to be such a major upgrade that more pumps at the site are being replaced with AHLSTAR pumps.