Custom seal solution reduces downtime for challenging pumping application.

Vulcan Seals provided a custom seal solution for a global manufacturer facing severe slurry substance challenges on positive displacement pumps. This innovation significantly reduced clogging, pump downtime, and maintenance costs while enhancing overall system reliability.

A multinational manufacturer faced persistent issues with traditional cartridge mechanical seal designs that employed multi-spring technology on positive displacement pumps. The application involved a challenging slurry substance of fine, soft, sticky particles interspersed with cellulose-based fibres. These conditions caused the mechanical seals’ moving parts to become quickly clogged, preventing the seal faces from correctly adjusting. As a result, leakage occurred shortly after installation. The result was frequent pump downtime where extended operating hours were interrupted by the need for unscheduled maintenance. Due to the cartridge mechanical seal’s short lifecycle (replacement needed after 72 hours), regular pump strip-downs and seal repairs and replacements significantly raised operating expenses.

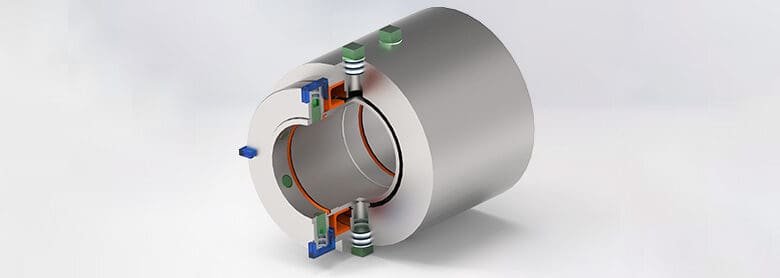

Vulcan Seals introduced the Vulcassette custom solution design, an innovative product that completely removed the springs used to energise the primary seal surfaces.

Removing springs meant there were fewer surfaces and mechanisms for slurry particles to accumulate, thereby reducing clogging.

The design simplified the energisation method and integrated carefully selected sealing materials to overcome chemical incompatibility and inadequate wear resistance, key issues that led to failures in traditional mechanical seal technology.

The new design also allowed the seal faces to re-adjust automatically, even after minor impacts or blockages.

And, although on this occasion, the manufacturer did not utilise the built-in seal cleaning system, the option to circulate cleaning water around the sealing face area further improves performance by preventing particle deposition.

The introduction of the Vulcasette enabled extended run times with the pumps operating for much longer periods between maintenance strip-downs, reducing process downtime.

With less frequent seal replacements and repairs, overall operating expenses were substantially lowered.

The self-adjusting capability ensured that minor leakages caused by oversize contaminants or impaction were promptly corrected without manual intervention.

While the Vulcassette design now allows adjustments to be made when the equipment is not rotating, eliminating the need for complete removal from the shaft during planned maintenance.