Countering pump failures

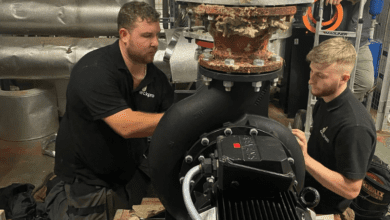

From worn bearings to a damaged seal, seemingly minor issues can lead to the shutdown of an entire pump system. Luckily, a preventive maintenance strategy can help identify potential threats before disaster strikes. Brian Tait, Head of Pump Services at electromechanical specialist Houghton International, explains how.

The specific maintenance requirements of industrial pumps depend on several factors, including the type of pump, the clarity and viscosity of the pumped medium, the compliance requirements of the specific industry sector and more. However, all industrial pump systems need regular maintenance to minimise costly, inconvenient, and possibly hazardous unplanned downtime.

Take the dairy industry as an example. If the pump seal in a UHT milk pasteuriser fails and a maintenance engineer cannot repair it quickly, the entire production batch will be destined for the bin. Now, imagine the same happening in a chemical processing plant where a pump is transporting hydrochloric acid for PH balancing – in this case, failures can lead to more than just financial losses. A careful inspection of the sealings could have identified the early signs of damage and avoided catastrophic failure in both cases.

Pump performance testing

Despite the clear advantages of preventive maintenance in terms of cost, improved efficiency and increased safety, from Houghton International’s experience, emergency repairs seem to be the prevailing method of caring for pumps. Instead, pump owners should take advantage of modern testing and condition monitoring systems, such as pump performance testing and vibration analysis. A pump performance test can measure the efficiency of the overall pump system, defined as the ratio of the delivered water horsepower and the brake horsepower delivered to the pump shaft. In a pump performance test, the efficiency level is represented by a curve that indicates how the pump works regarding pressure and flow.

One of the parameters measured by the test is the best efficiency point (BEP) – the point on the curve that leads to the most efficient operation. Efficiency will be at zero when the discharge valve is closed, and there is no flow. As the discharge valve opens and the flow increases, efficiency will increase too. It will then decrease again as the flow becomes more turbulent and congested.

Somewhere between zero and excessive flow, there is a flow rate that leads to ideal efficiency – the BEP.

To be 100% efficient, the horsepower input should be the same as the water horsepower output. This is never the case due to normal causes of energy loss such as friction and leakages. Consequently, a 75% efficiency rate is considered optimal, while 50% or lower indicates a potential issue.

Vibration analysis

Pumps produce vibrations that appear at specific frequencies across a wide spectrum. Pump spectral analysis examines these frequencies to identify problems such as misalignment and imbalance, flow pulsation, a bent or damaged shaft, bearing failure and cavitation.

A vibration reading of 1-2mm/sec is generally considered healthy. Based on the type of pump, the specific application and the medium being pumped, a qualified technician can advise on the proper course of action when vibration exceeds this threshold. Because of the many variables to consider, pump owners who opted to have a vibration sensor installed should discuss with a trained professional what a healthy vibration range should look like in their system and should not be tempted to simply increase the threshold when the sensors flag up an issue.

In critical equipment, such as industrial pumps, seemingly minor issues can quickly turn into major headaches. By taking a preventive approach to pump maintenance, pump owners can ensure their operations keep flowing.