Maintenance

The latest maintenance related articles for users of pumps and pumping systems

-

ABB study details the bottom-line impact of system breakdowns

A new global report from ABB titled ‘Modernization for Resilience’, developed in partnership with Sapio Research and based on a…

Read More » -

Team Repair and iFixit partner to take repair learning global

Team Repair, the UK start-up founded by engineers from Imperial College London, has joined forces with iFixit, the world’s largest…

Read More » -

The link between the total cost of ownership and refurbishment and upgrade

Mark Brady, Director at HAYLEY 247 DEXIS, looks at the role that the repair and refurbishment of electromechanical equipment can…

Read More » -

Having a breakdown? Let’s talk about it

In an increasingly digital world and now with the potential impact of AI on all our futures continuing to grab…

Read More » -

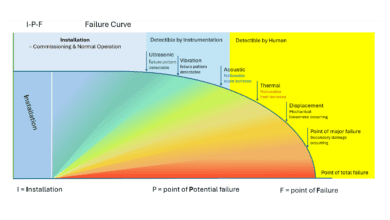

Begin your condition monitoring journey

Reliability engineering and in particular condition monitoring is a mature and complex engineering subject and for those not from a…

Read More » -

Simplified industrial device maintenance with Generative AI

ABB has launched My Measurement Assistant+, which the company says is the first AI-powered digital solution for maintenance and troubleshooting…

Read More » -

Focusing on the driven component

With electric motors creeping upwards in terms of efficiency, the savings to be made by moving between IE classifications are…

Read More » -

Electronics repair: Busting the myths

William Santos from ABI Electronics, who’s been championing the importance and value of carrying out electronics repairs for the last…

Read More » -

Creating a reliable maintenance plan

When pumps fail, the consequences can be severe, from flooding and water damage to complete operational shutdowns. One effective way…

Read More » -

A second life for obsolete pumps

When “aged” machinery in a system fails, spare parts are often no longer available. Buying a new machine is costly…

Read More »