A perfect match for high efficiency drinking water pumps

flow found out why Dutch pump manufacturer, Rodelta has introduced drinking water pumps powered by ABB’s SynRM motors.

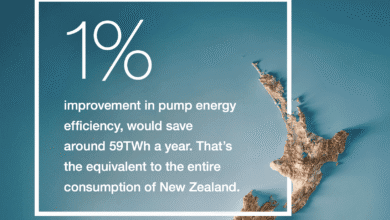

Synchronous reluctance (SynRM) motors save energy, cut energy bills and reduce emissions in water pumping applications. The pumps feature diffuser technology and are designed with a wide operating range to handle large variations in water demand. SynRM motors have proven to be an excellent fit for the application.

“We supply our LS diffuser pumps for drinking water pumping stations because they offer high efficiency over a wide operating range. ABB SynRM motors are ideally suited for driving the pumps – they are very efficient across the entire range,” said Andre van der Moolen, Sales Engineer, Rodelta.

There are clear reasons why Rodelta focuses on this type of technology in the drinking water pump market. The pumping stations often run 24/7, so efficient equipment can quickly produce big energy savings. In terms of the total cost of ownership, the motor and pump typically account for around 20% of total lifetime costs, with energy consumption making up the remaining 80%.

IE5 ultra-premium efficiency

“SynRM motors offer IE5 ultra-premium efficiency,” said Michel Jansen of ABB in the Netherlands. “Advanced technology and high efficiency mean they cost a little more than regular induction motors, but SynRM motors use much less energy. When energy prices are around their long-term average, the payback time for purchasing an IE5 SynRM rather than an IE3 induction motor is around 18 months. High energy prices mean accelerated payback, and payback times of just a few months are possible. Once payback is achieved, the SynRM keeps on saving energy over its entire lifetime.”

Another advantage of SynRM motors in pumping applications is their lack of slip. In an induction motor, the shaft rotates at a lower speed than the synchronous speed, and this difference is known as slip. When an induction motor drives a pump, slip can be particularly marked during the start-up phase. As a result, a larger – and therefore more expensive – motor tends to be specified. Switching to SynRM, a synchronous technology with zero slip, often means that a motor one frame size smaller can be selected, which produces an immediate saving.

Boosting sustainability

Lower energy consumption helps to cut emissions of greenhouse gases, making SynRM motors a more sustainable choice than induction motors. A further sustainability benefit is that SynRM motors do not contain any rare earth materials, unlike permanent magnet motors.

“At Rodelta, we are proud of our efforts to design more efficient pumps that help to save energy and cut emissions, and SynRM motors support us in these efforts,” Andre added.

Rodelta’s first two LS pumps with SynRM motors have been installed at a pumping station in Leut, Belgium. The motors are rated at 132 and 75kW and drive pumps with capacities of 350 and 240m3/hr. The facility is operated by De Watergroep, the largest drinking water company in Flanders.

De Watergroep had already used a SynRM motor and requested the same type of motor for its new drinking water pumps. In fact, there are signs that SynRM technology could become the preferred choice for driving drinking water pumps, with water supply companies in the Netherlands also showing interest.