A fire extinguishing system with maximum flexibility

Power management specialist, Eaton, explains how Alfred Schneider GmbH, a leading manufacturer of protective cabinets for fire extinguishers and water-based fire extinguishing products, has used its DG1 variable frequency drive to develop a highly flexible variable-speed booster pump system that can be adapted to a wide range of requirements, for example buildings with multiple pressure zones.

The booster pumps in fire extinguishing systems ensure enough water is available at the hose connection points or fire hose reels installed inside a building. The system uses a pump to increase the water pressure in the pipes to the required level. But, despite all the recent developments in drive technology, pumps are still often switched using contactors. “This particular industry is very conservative when it comes to new technologies,” said Lars Biskupek, Head of Fire Protection at Alfred Schneider GmbH. “In general, people are sceptical of electronic systems because it is often believed that they offer limited reliability in an emergency.”

The disadvantages of contactors

The traditional design of contactor systems comes with certain disadvantages: On the one hand, water-based fire extinguishing systems that are switched using contactors can only run at a specific speed, so the pump power and water pressure cannot be adjusted. This is sufficient for ‘simple’ fire extinguishing systems. This type of contactor-based set-up gets more complicated; however, if different extinguishing devices need to be connected to the same water pipe, each of which requires a different level of pressure. On the other hand, starting the pumps this way also generates a high starting current. This places a high load on the grid and the entire electrotechnical equipment. During operation, i.e. when pumping large amounts of water for fire extinguishing purposes, overcurrents can also occur, as Lars explained: “The pumps have been designed with a specific capacity in mind. If this capacity is exceeded – for example, because water is taken from too many fire hose reels at the same time – the system will operate outside its intended characteristic curve, which will result in an overcurrent. As the applicable standard prohibits the use of motor-protection devices to prevent the motor from shutting down, there is a risk that the emergency generator will fail as a result.” For Alfred Schneider, this was the decisive factor in the decision to redesign the drive technology of its booster pump system so that it could be safely powered by emergency generators.

The perfect solution

The company decided to use variable frequency drives to develop a fire extinguishing system with a variable-speed booster pump. The contactor was thus replaced with an Eaton PowerXL DG1 variable frequency drive. “The DG1 comes with an integrated fire mode as standard,” which according to Lars, was one of the reasons the company chose this particular product. This fire mode – which is also offered by Eaton’s compact DC1 drive for less complex applications – deactivates the internal protection functions. When this mode is activated, the motor-protection devices in the pump circuit will only be used to signal a fault but not to shut down the pump. As such, the drive also meets the requirements of DIN 14462 and the VdS guidelines. If the booster pump system itself is exposed to fire, smoke or high temperatures, it will continue to operate even if the thresholds or response values are exceeded, reliably supplying the fire hose reels or sprinklers with water for as long as possible. The fire mode can be configured using a range of options, including fixed setpoints, switchable setpoint inputs and fail-safe activation. The DG 1 is also robust and heat-resistant. Alfred Schneider uses an IP54 variant that can be installed outside the control panel and therefore requires no ventilation or cooling.

Safe current limiting

“Most importantly, however, the drive also comes with a current limiting function,” added Lars. On the one hand, the drive can be configured in such a way that the starting current does not exceed the rated current of the emergency generator. As a result, the generator can be configured based solely on the requirements of the other building services – the high starting currents that were caused by the contactor-based system in the event of an emergency (or during tests) no longer need to be taken into account. For operating the equipment under emergency conditions, Alfred Schneider’s experts have also programmed the DG1 to reduce the speed in the event of excessive current consumption. Although this reduces the water pressure at the outlets, the current will be back to normal – thereby protecting the emergency generator against damage or even failure. This considerably increases the operational reliability of the entire system.

Up to four pressure zones

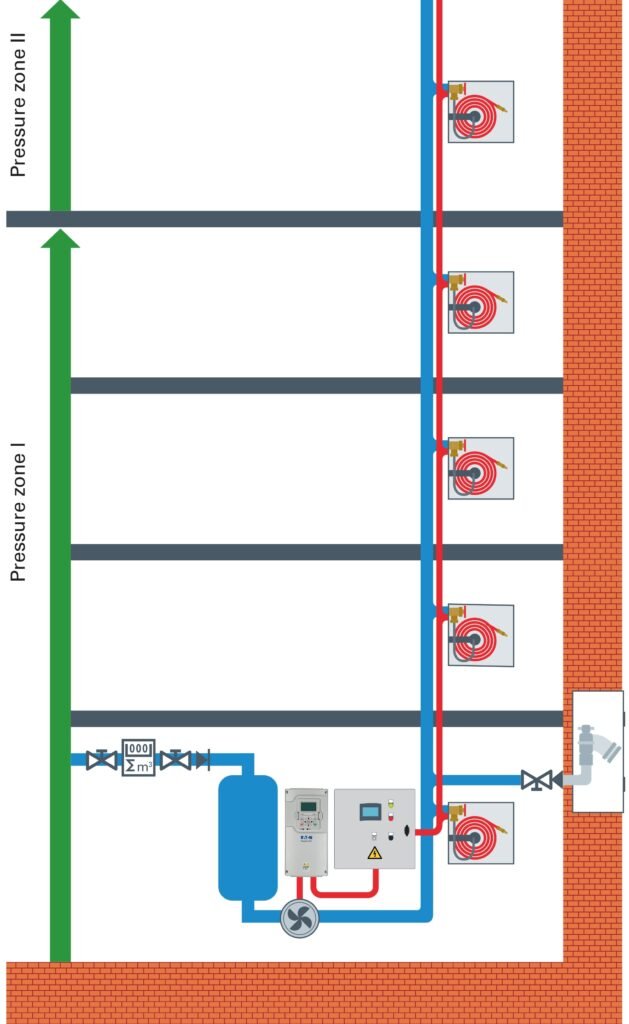

Controlling the booster pump system by means of a variable frequency drive also offers additional advantages: “We can achieve a very high level of flexibility in terms of adapting the system to local conditions,” continued Lars. “For example, the DG1 makes it possible to configure up to four different pressure zones. This means, for instance, that the speed can be controlled in such a way that each outlet is supplied with the appropriate level of pressure for that particular type of outlet. We implemented this in the fire extinguishing system of an industrial facility, where the same system is used to supply water at 1.5 bar to fire hydrants and at 4 bar to fire hose reels”. The outlets are equipped with contacts, thanks to which the drive ‘knows’ which outlet has just been opened, and will then ensure the necessary level of pressure by adjusting the pump speed. “Depending on which extinguishing device is used, we can optimally adjust the pressure in the pipe via the variable-speed booster pump system,” noted Lars.

In another application, Alfred Schneider installed a variable-speed booster pump system to compensate for a leaky underground water pipe and to ensure sufficient levels of pressure. As soon as the pressure in the pipe drops below 0.5 bar on account of the leakage, the drive will start up the pump and bring the pressure level. And in the event of a fire, the pressure level will be raised to 6 bar while the water is being drawn. In addition, the pressure can also be readjusted via the variable frequency drive: If a hydrant is opened, for example, the pressure in the pipe will drop. With variable speed control, the pump output can be gradually increased until the desired or required level of pressure has been restored. The level of pressure is monitored by means of a pressure sensor inside the water pipe.

Different pressure zones

In high-rise buildings, the Eaton DG1 can also be used to configure up to four separate pressure zones. If a fire hose is opened on a particular floor, the drive will raise the pump output only to the level that is actually required to ensure the right amount of pressure. For this purpose, a limit switch is installed at each outlet – i.e. at the fire hose valve – that will indicate if it has been opened. Via fireproof cables (which are also monitored for open/short circuits), the switches are individually routed to the control system, which will then communicate the required pressure level to the drive, depending on which valve is actually open. As such, the control system receives reliable information about the exact floor and pressure zone where the fire is being fought. However, this is a custom solution that may only be implemented with a special permit from the responsible fire protection authority in Germany. Multiple pressure zones are only mandatory for buildings higher than 35m. So far, one pressure zone was sufficient for most of the systems that Alfred Schneider has implemented because the height of the buildings (including numerous apartment buildings in Hamburg) did not exceed 30m. While the system relies on conventional wiring, Eaton’s DG1 also offers communication interfaces for various bus systems, including Ethernet and BACnet, which are widely used in building services engineering.

Thanks to the DG1 drive from Eaton, Alfred Schneider was able to develop a variable-speed booster pump system that can be adapted to various building types and requirements. By reducing the load, the drive’s integrated current limiting function also enables the use of smaller emergency generators – but more importantly, the drive protects the generator against overcurrents. All in all, this reduces the power consumption of the entire system, which also lowers the capital costs. By using contacts or pressure sensors to control the system, different levels of pressure for different outlets can easily be implemented. In addition, the ‘soft’ starting of the pump protects the entire system and subjects it to significantly less mechanical stress compared to switching via contactors.