Flow magazine takes a look at the seven projects shortlisted in the ‘Project of the Year’ category at the 2022 Pump Industry Awards, which were held in March this year.

In a hotly contested category, the coveted Project of the Year award was picked up by SPP pumps for its work to re-engineer a large 53-year-old split case pump.

SPP received the pump, which was used in a brine transfer application, in very poor condition, and it was clear that it needed to be replaced. However, it was an obsolete design from the 1960s that was no longer available.

In addition, due to the surrounding plant layout, it was not possible to install a new alternative pump without significant piping, civil and structural modifications.

SPP had to find an alternative solution and took on the task of reverse-engineering the obsolete pump and manufacturing an identical replacement.

The company’s engineers scanned the top and bottom casings with a 3D laser scanner and captured the existing pump surface data in a mesh form. Using this information and elements of original drawings held by the pump’s user, dimensional drawings and 3D models of the pump’s components were produced. From this data, SPP was able to cast new casings from an NI Resist iron which suited the pump’s application, produce a new impeller and machine the other parts, including shafts and sleeves.

The new pump was then assembled before being delivered to site for installation in time for a planned shutdown. The pump was fitted into the existing footprint and connecting pipework without issue and, upon commissioning, was found to run smoothly, capable of delivering the required process flow of 22,000 GPM at 20ft head.

Re-engineering the pump cost SPP’s customer less than half of the cost of a new alternative – maybe even a quarter of the cost had the civil and structural engineering changes been needed on site. In addition, the customer now has full drawings and data to enable the production of new parts should they be required in the future.

LEACHING PUMPS

Baker Hughes submitted a project based around the supply of leaching pumps to a gas storage facility. The pumps are designed to move huge ‘soft water’ streams to dissolve the salt located on the cavern walls and then, in a second phase, bring the salted water out of the cave back into a salt lake.

Heavy-duty multistage axially split type pumps of Super Duplex construction, driven by a 7MW electric motor, were selected for the project. Coupled with variable frequency drives, which adjust the speed and performance to match the process requirements perfectly, they delivered a flexible service.

The solution chosen, coupled with a lean manufacturing approach, enabled the project to be completed in a short timeframe and without interruption, which maximised the reliability and availability of the site, while the highest available level of efficiency was also achieved.

FISH-FRIENDLY PUMPING STATION

A project requiring fish-friendly axial flow concrete casing pumps for a new high-capacity pumping station in the Islington catchments was put forward by Bedford Pumps.

The pumping station was required to accommodate a significant variation in flow rates, ranging from dry weather flows to 1-in100-year storm conditions, all whilst maintaining required efficiencies. Four variable speed drive pumps, each delivering into its own independent rising main, were provided, each capable of a maximum flow of 4m3/sec with a turn-down to

2m3/sec. Pump efficiency is maintained above 80%, rising to 86%, thus minimising power consumption and associated carbon footprint.

In addition to developing a unique higher efficiency axial flow variant of a concrete casing pump, Bedford Pumps also developed a new formed suction intake for the project. This allowed for incredibly low operating water levels on site, at half of the minimum submergence of a standard ‘type 10’ design. Combining the pump design with the intake provided a very low footprint, significantly reducing the excavation costs on site by allowing the pipework to be closer to the surface. These intakes can operate at a total station capacity of 20,000 l/sec, thus proving the infrastructure futureproof.

The original 1950s pumping station had significant reliability problems and could no longer adequately protect the area. The four replacement pumps can pass 1.4 billion litres of water daily and provide flood protection to 9,700 hectares, including 1,500 residential and 500 non-residential properties, strategic roads connecting rural communities and 6,700 hectares of agricultural land.

FOUL PUMPING STATION

The project submitted by Campion Pumps covered the design, installation and commissioning of a foul pumping station to serve an extensive suburban area development with zero gravity to mains in Co. Dublin, Ireland. As part of a project to provide vital housing

in the area, pump efficiency was a critical element of the design, as was the capacity to support the high usage of a suburban development, which included 600,000 litres of storage capacity, 2,240 houses, 16 Schools and 825 retail units.

The initial project specification sought two fixed-speed 18kw pumps. However, Campion’s engineers convinced the client of the increased energy savings and reduced maintenance costs available by using three Flygt Concertor variable speed foul system pumps, due to the varying flow demands over a 24hr period.

The improved pump specification will save the client thousands of Euros in reduced maintenance costs and the high energy efficiency of the variable speed pumps over their lifetime.

The implementation of the Campion Connect cloud-based SCADA monitoring system provided a real-time web-based platform for the customer to view the whole pumping operation. If a pump goes down, causing disruptions to the sewage pumping requirements, this will be detected, and an alert will be sent in time to implement a solution.

SULPHURIC ACID TRANSFER

When a bank of stainless-steel mag-drive pumps for 96% sulphuric acid transfer from a bulk storage tank to a process was constantly being repaired and not performing as originally intended, Crest Pumps was called in to investigate. By carrying out a pipework survey taking elevation and pressure readings to determine why the pumps weren’t performing and after accounting for density adjustment, it was established that the pumps were running very close to closed valve pressure. This was because the pumps were originally selected severely left of curve to accommodate a specific gravity of 1.84 and ensure the magnets were not over-loaded. This meant the pump was grossly oversized for the application.

Crest Pumps recommended the installation of its Crest Assoma magnetic drive pumps. In addition to significantly increased transfer rates and vastly improved reliability, the client is making significant financial savings. These come not only from reduced maintenance and downtime costs but also from a 20% reduction in energy consumption.

MOBILE WASTE PUMPING STATIONS

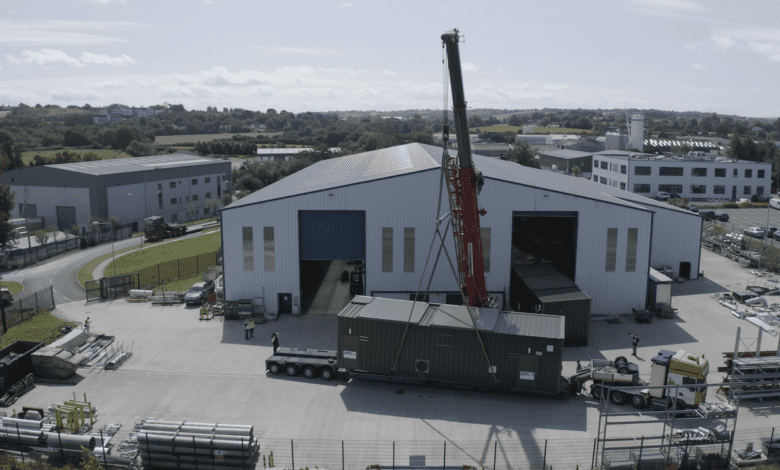

A project entered by Drilling & Pumping Supplies (DPS) outlined how it had worked with Northern Ireland Water (NI Water) to develop two mobile waste pumping stations to be installed on its network.

The two pumping stations had duties of 24MLD at 16bar and 18.5MLD at 13.5bar, and both consisted of four KSB Multitec pumps. One used 4 250kW 4-pole motors powered by variable speed drives, and the building was 13.5m long, 4.2m wide and 4.2m high, with a total dry weight of 42 tons. The other used four 110kW motors to power the pumps, while the associated services within the building also required innovative detailed designs.

As the first project of its kind for NI Water, and due to the scale and complexity of the scheme, it required an innovative approach to off-site and modular building. The water pumping stations had to be mobile and also able to withstand significant thrust forces and be safely transferred into the groundworks. The off-site design advances challenged the current asset standards and formed a road map to allow NI Water to create a new asset standard that can be replicated across the network with the main aim of providing a mobile plant that could be re-positioned to meet network or emergency demands.

LASER METAL DEPOSITION

Sulzer used laser metal deposition (LMD) to repair a Super Duplex lean amine pump impeller that had suffered from cavitation damage in the project it submitted to the awards.

Tungsten inert gas (TIG) welding causes heat distortion in Super Duplex, making it unsuitable for the repair.

LMD requires considerable expertise to assess each component and select the necessary consumables, control parameters and techniques to deliver a durable repair.

For greater flexibility and access, a semi-automated process was selected using a manual wire feed and automated control of the laser head. In between each pass of the LMD head, a cooling period was required to ensure the temperature of the repair site did not exceed 100°C.

The repaired impeller provides as-new performance, efficiency and durability. In an application where cavitation is unavoidable, and Super Duplex is the optimum impeller material, the ability to return a damaged component to its original dimensions and performance is invaluable.