Prevent recirculation pump failures with water and wastewater drives

Flow discovered how the pump cleaning function in ABB’s water and wastewater drives helps prevent damage to wastewater pumping operations.

The Sewage Treatment Plant for Research and Education Das Lehr- und Forschungsklärwerk (LFKW) at the University of Stuttgart in Germany is a facility for wastewater and wastewater treatment and a platform for education, research and demonstration. It is a place where scientists can practically test new wastewater treatment processes comprehensively. LFKW treats wastewater from the Stuttgart area, including parts of the Vaihingen-Pfaffenwald University area. The volume of wastewater treated annually is around 800,000m³. The pollution load supplied corresponds to a volume of approximately 10,000 inhabitants.

The pump in use at LFKW recirculates wastewater with activated sludge from the aeration tank to upstream denitrification. The solids content in the aeration tank ranges from 4g/l to 5.5g/l. A high-efficiency pump was selected since a continuous-duty pump is used at the location. After a new dual-channel impeller pump was installed, overloads occurred within a few days due to very high current consumption, and the motor burned out on two occasions. The manufacturer came back with information suggesting that contamination and deposits in the pump would have generated these overloads.

Figure 1: Normal operation (graphic: iswa.uni-stuttgart).

The pump had to be replaced three times within two years because fibres and sludge residues had settled in the gap between the channel impeller and the housing which resulted in increased current consumption, and eventually damaged the motor. The imbalance caused bearings to fail, or the winding would burn out due to high current consumption. Replacing the pump involved a lot of effort each time. A crane truck was required to lift the pump where it was installed in the sewage treatment plant.

Pump cleaning to prevent blockages

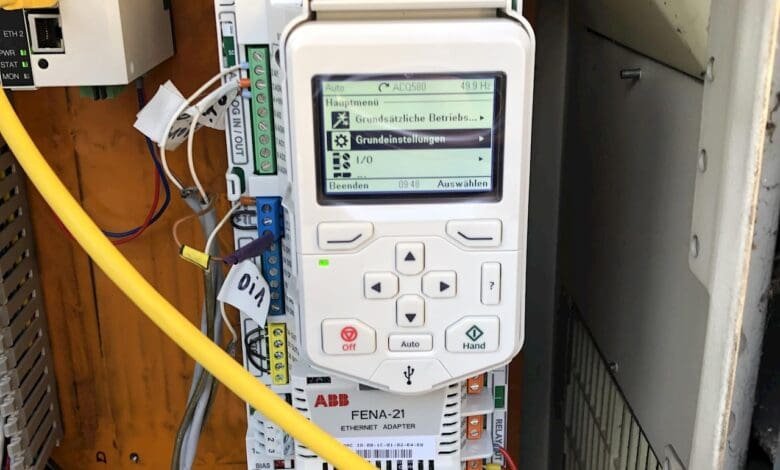

To correct the problem, ABB’s ACQ580 variable speed drive with 4kW of power was installed for motor control in February 2021. The drive has been specially designed for water

and wastewater applications. The integrated pump cleaning function in the drive is particularly suitable in this situation. It is intended to prevent solid particles from becoming lodged in pump impellers or piping. Traditionally, the blockages would be removed manually, but this requires the pump to be decommissioned and opened.

Figure 2: Operation with increased cleaning effort (graphic: iswa.uni-stuttgart).

The pump cleaning function in the ACQ580 consists of a programmable sequence of forward and backward rotations to loosen and remove deposits from the pump impellers and piping. It prevents blockages, making the need for manual cleaning less frequent.

The drive starts the cleaning process by applying a pulse in the direction opposite to the operating direction. The duration of the cleaning pulses is the same in both positive and negative directions. Several cleaning pulses in the positive and negative directions can occur within the same cleaning sequence.

Secured flow of wastewater

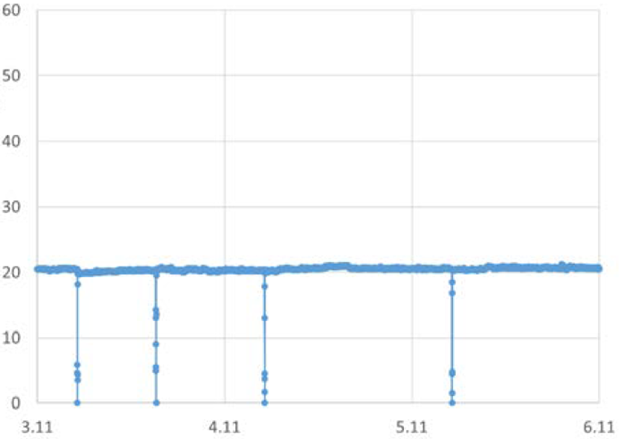

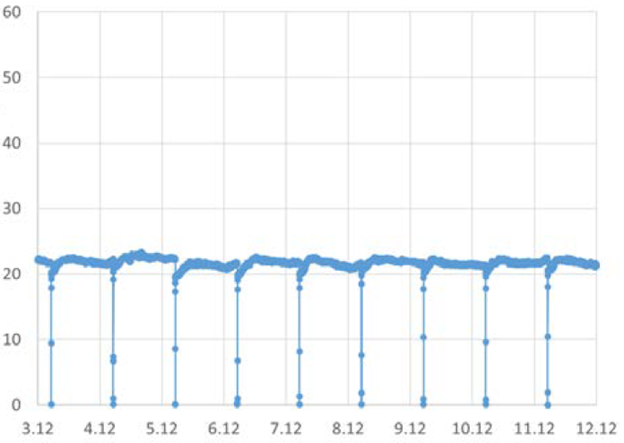

The ACQ580 operates the pump’s motor at a frequency of 48Hz. The target is a constant flow rate of approximately 20l/sec, as a uniform recirculation rate is essential for the process. The flow rate should be kept constant to achieve a high denitrification rate.

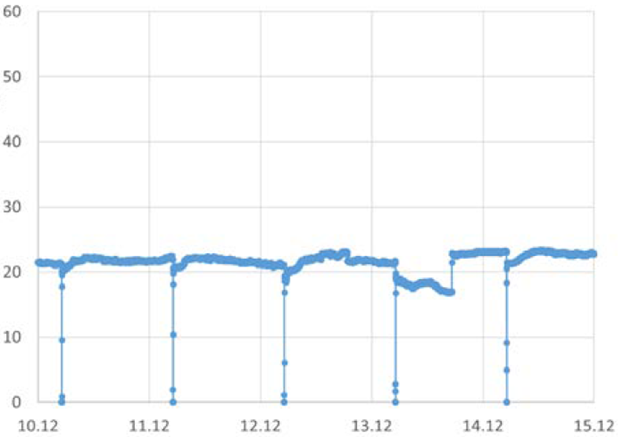

Figure 3: Increased cleaning effort (graphic: iswa.uni-stuttgart).

Since the ABB ACQ580 has been in operation, it is clear that the self-flushing of the pump is working again. The flow rate decreases slightly at a constant speed over the day and increases again after cleaning.

Figure 1 shows how the trouble-free operation works. The pump operates at a constant speed, and the drive monitors the power consumption. The pump is usually reversed once a day. If increased power consumption values start to appear, the drive stops, runs an automatic cleaning program and then restarts at the set point speed. In trouble-free operation, the flow rate at constant speed is the same before and after flushing. Flushing is performed depending on the pollution. So, in the example shown, flushing was run twice on November 3, 2021, and once a day on other days.

If increased pollution occurs, the delivered flow rate fluctuates at a constant pump speed. This can be caused by deposits in the pump chamber, in the wear rings of channel impellers or in the suction or pressure nozzles. Figure 2 shows one such example. After flushing, the flow rate increases and then steadily decreases. Then, the circuit is flushed, and the pollution is rinsed out. This causes the pump to deliver more water again at the same speed.

Figure 3 shows 24-hour cycles without heavy pollution on December 10 and 11, 2021. On December 13, the flushing program started, but the pump did not immediately deliver the desired flow rate since dissolved pollution needed to be rinsed out. The pump will not give the expected flow rate until it has fully rinsed everything out.

The results show operation at a constant rotational frequency. That’s why the flow rate fluctuates. If the pump is operated with rotational frequency control and a fixed flow rate, the comparable effect can only be detected in the power consumption and the speed (frequency).

Smooth pumping

A dual-channel impeller pump at LFKW that pumps recirculation water from the aeration basin to the denitrification basin has seized repeatedly in the past as a result of pollution, resulting in total pump damage. Since installing the ABB ACQ580 water and wastewater drive with built-in pump cleaning functionality, the pump has been running trouble-free and with low wear. Overloads did not occur, and bearings no longer needed replacement. The experience gained at LFKW can be transferred to all wastewater treatment plants. If there is a risk of clogging, clogged areas can be loosened using the pump cleaning function of the drive, and doing so will not block the pump either on the suction side or the pressure side.